CNC Machining

Reverse Enginnering & Prototyping

Fixturing & Workholding

Assembley & Cleaning

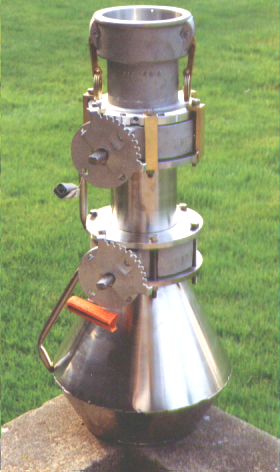

Old or outdated parts are often without drawings and are no longer available for purchase. Bring us your item and we will reverse engineer it to the exact dimensions, enabling us to create drawings and remanufacture the new part.

With a variety of machines, and by maintaining a low overhead, we are capable of producing prototype and small quantity parts with competitive pricing and quick turn around times. Lead time for prototype parts is typically under two weeks, enabling you to proceed with your project, avoiding project delay.

Quality is the most important service PicoPascal offers. In-process inspection reports are completed during machining processes to assure parts comply with drawings and catch any errors before further production is completed.

With high quality late model CNC machine tools, PicoPascal is capable of manufacturing single part quantity to large production quantity runs.

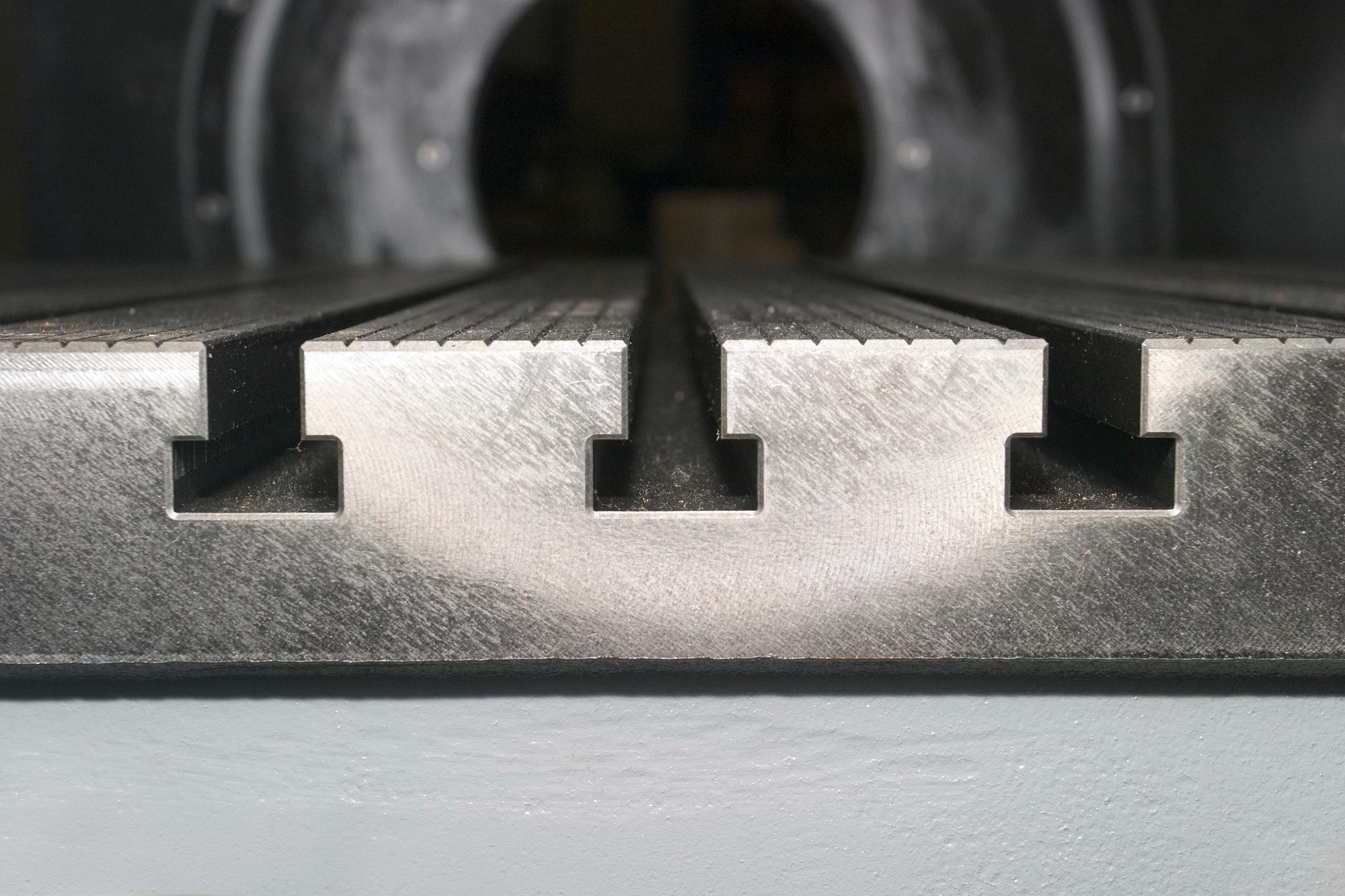

Our advanced CAM (computer aided manufacturing) software, paired with 3 and 5 axis CNC machining centers, allows us to machine complex parts with tight tolerances in a wide range of materials. The milling department offers small to medium sized parts ranging from low to medium quantity production runs.

High precision CNC lathe allows us to achieve highly efficient per part run times and competitive costs. Medium to high quantity production runs are achievable.

Other Services

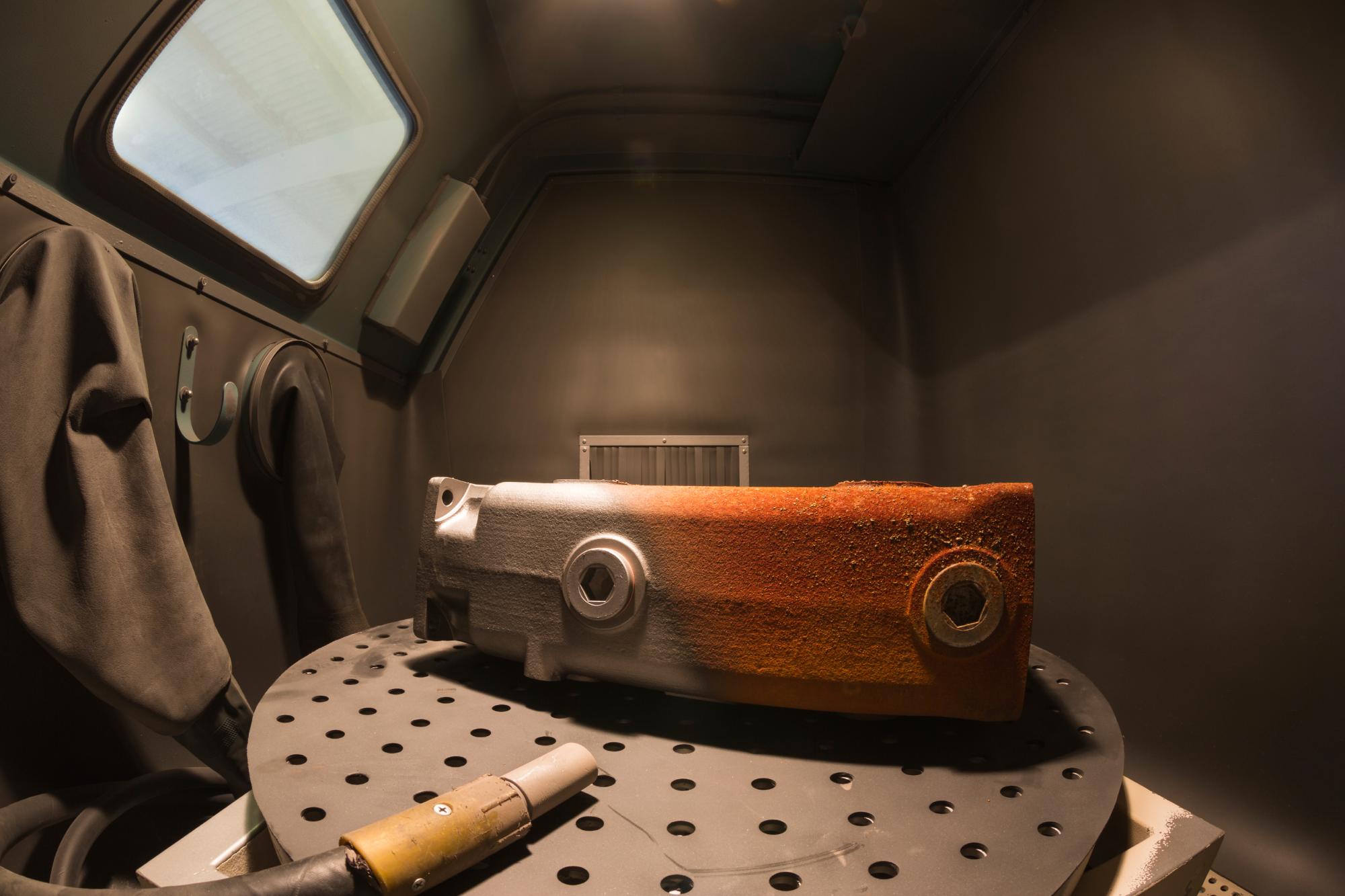

MIG/TIG Welding Bead Blasting